BLOG

Finishes That Last - Materials, Coatings, and Rooftop Performance

The short version

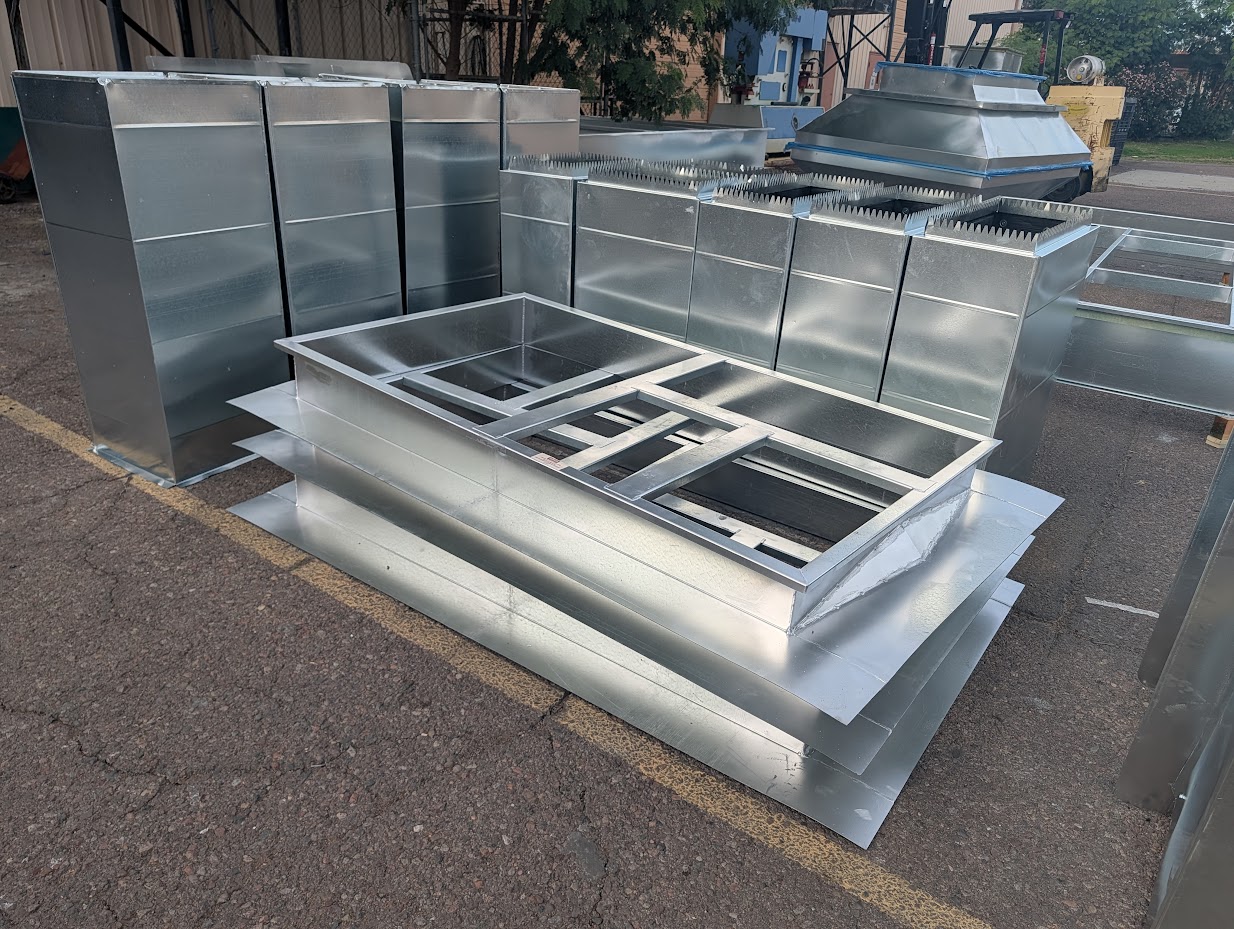

On the roof, finish is protection. We start with G90 galvanized steel on purpose, then protect seams and edges so the product ages evenly over time.

Most people think finish means color. In fabrication, finish means survival - sun, heat cycling, condensation, rooftop runoff, and years of real exposure.

At Empire Metal Products, we choose materials and finishes based on performance first. The goal is simple: duct, curbs, adapters, and rooftop products that stay in service long-term without slowly corroding at the seams.

Standard material for duct, curbs, and roof products

G90 galvanized steel

Protected at the most vulnerable point

Weld seams treated with enamel

When appearance and durability both matter

Pre-coated sheet, powder coat, and material upgrades

Our Standard: G90 Galvanized Steel

All of our ductwork, curbs, adapters, and rooftop accessories are fabricated from G90 galvanized steel as standard.

Galvanizing is rated by zinc coating weight. That coating is what protects the base steel from oxidation caused by moisture, condensation, rooftop runoff, and years of thermal cycling.

Why G90 matters long-term

- More corrosion resistance at cut edges and fastener points

- Better durability through heat cycles and rooftop exposure

- More forgiveness for handling and minor surface wear

- Longer service life before corrosion becomes a concern

Many shops quietly downgrade to lighter coatings to save cost. The product may look fine on day one. Years later, corrosion shows up where it always starts - seams, edges, and hardware.

We do not build that way. G90 is our baseline because rooftop steel should last.

Moisture

condensation, ponding, and runoff

Sun exposure

UV, surface bake, and daily heat load

Heat cycling

expansion, contraction, and fatigue

Exposure

airborne grit, fallout, and debris

Handling

rigging, service traffic, and maintenance

Weld Seams and Cut Edges: Where Corrosion Starts

Even with galvanized material, weld seams and cut edges deserve attention. Welding naturally removes the zinc coating at the seam. That location becomes the first place corrosion begins if it is ignored.

After fabrication, we treat exposed steel at weld seams with a protective enamel coating. This restores corrosion resistance where the zinc layer has been burned away.

- Seals exposed steel at seams, corners, and attachments

- Protects stress points that see standing moisture and handling

- Helps the product age evenly instead of failing early at the seam

Practical reality

This is not about making it look painted. It is about protecting the exact locations where corrosion would otherwise start first.

Painted finishes

In some applications, paint adds real value - visibility, identification, and a finished look in customer-facing areas.

- Equipment screens and architectural elements

- Components requiring color matching or visual integration

- Parts exposed to specific site conditions that benefit from added coating

- Interior-facing or customer-visible areas

- Safety color coding and zone identification for facilities and service teams

- When the finish needs to be touch-up friendly in the field

- When color consistency matters across multiple site components

- When visibility and presentation are part of the spec

We use professional-grade coatings selected for adhesion, durability, and UV resistance. The goal is performance, not just color.

Powder-coated finishes

When long-term appearance and surface toughness are critical, powder coating is often the best choice. It provides a thicker, uniform protective layer with strong resistance to chipping and abrasion.

- High-visibility rooftop work where appearance stays under scrutiny

- Parts that get touched, walked around, or serviced regularly

- When you need a uniform finish without streaks or thin spots

- When abrasion resistance matters more than touch-up convenience

Powder coat is not just “prettier paint.” It is a tougher film build that holds up better to handling and rooftop wear. If the job is customer-facing or gets serviced often, this is usually the finish that looks right the longest.

We coordinate powder-coated work through trusted finishing partners so you get consistent results and predictable timelines.

Stainless Steel and Aluminum Applications

In some environments, galvanized steel is not the right answer. When corrosion resistance must be absolute or weight matters, material selection becomes the finish.

Stainless steel

For harsh environments and long-life performance.

- Commercial kitchens and grease duct applications

- Washdown environments and high humidity rooms

- Chemical exposure and corrosive atmospheres

- Long-life installations where coatings are a liability

Aluminum

For weight-sensitive parts and rust-free performance.

- Weight-sensitive rooftop components and panels

- Equipment screens and architectural trim

- Non-structural enclosures where handling weight matters

- Projects where rust prevention is a must

For roofing and architectural applications, pre-coated steel and aluminum sheets offer durable factory finishes in many colors and textures, designed for exterior exposure.

Appearance

consistent color and clean finish

Outdoor durability

UV and weather-ready coatings

Best use cases

screens, panels, wraps, visible faces

Finish decision framework

What we consider before recommending a finish or material.

Quick finish selection checklist

The questions that prevent surprises after installation.

- Interior or exterior exposure

- Direct sun and heat cycling

- Moisture, condensation, or pooling water

- Chemical exposure or washdown

- Handling and abrasion risk

- Visibility to customers and inspectors

- Expected service life

- Need for consistent site colors

- Maintenance and touch-up expectations

- Timeline and lead time needs

- Product type (curb, adapter, duct, screen, enclosure)

- Install environment (roof, mechanical room, outdoors)

- Any facility color standard or finish preference

- Photos of the install area if available

- Timeline (especially if powder coat is specified)

Our baseline approach

- G90 galvanized steel for duct and roof products

- Weld seams protected where zinc is burned away

- Pre-coated panels when appearance matters outdoors

- Powder coat when presentation and abrasion matter

Get the right finish the first time

Tell us where the part will live (roof vs interior), what it needs to endure, and whether it’s customer-visible. We’ll recommend the cleanest long-life material and finish for the job.

Get a quote todayContact

Contact Us

Reach out to us today to see how we can meet your project needs. You can also reach us by phone at 602-424-9980 during business hours.